| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | Bicheng |

| Model Number : | BIC-332.V1.0 |

| Certification : | UL, ISO9001, IATF16949 |

| Price : | USD9.99-99.99 |

| Payment Terms : | T/T |

| Supply Ability : | 5000PCS per month |

| Delivery Time : | 8-9 working days |

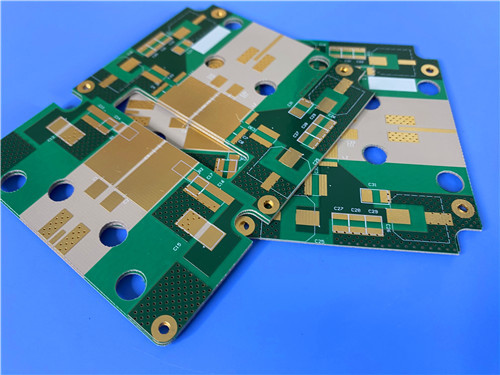

This 2-layer rigid PCB is tailored for high-frequency applications (exceeding 40 GHz), leveraging Rogers RO3203—a ceramic-filled, woven fiberglass-reinforced laminate—to deliver exceptional signal integrity, mechanical stability, and cost-effectiveness.

PCB Specification

| Parameter | Details |

| Base Material | Rogers RO3203 (ceramic-filled, woven fiberglass-reinforced PTFE composite) |

| Layer Count | 2-Layer (rigid structure) |

| Board Dimensions | 74.57mm x 23.28mm per piece (1PCS), |

| Minimum Trace/Space | 4 mils (trace) / 7 mils (space) |

| Minimum Hole Size | 0.2mm |

| Vias | No blind vias; via plating thickness = 20 μm |

| Finished Board Thickness | 0.35mm |

| Finished Copper Weight | 1oz (1.4 mils) for outer layers |

| Surface Finish | ENEPIG |

| Silkscreen | White silkscreen on top layer, no silkscreen on bottom layer |

| Solder Mask | Green solder mask on top layer, no solder mask on bottom layer |

| Quality Assurance | 100% electrical testing conducted prior to shipment |

PCB Stack-up Configuration

| Layer Name | Material | Thickness |

| Top Layer (Copper_layer_1) | 35 μm thick copper | 35 μm (1oz) |

| Substrate Layer | Rogers RO3203 | 0.254mm (10mil) |

| Bottom Layer (Copper_layer_2) | 35 μm thick copper | 35 μm (1oz) |

Rogers RO3203 Material Introduction

Rogers RO3203 is a premium high-frequency circuit material designed as an extension of the RO3000 Series, with a key focus on improved mechanical stability without compromising electrical performance. As a ceramic-filled laminate reinforced with woven fiberglass, it balances three critical attributes: exceptional electrical performance (suitable for frequencies beyond 40 GHz), robust mechanical stability, and competitive pricing—making it ideal for volume manufacturing of high-frequency devices.

Its core electrical properties—dielectric constant (Dk) of 3.02 and dissipation factor (DF) of 0.0016—enable reliable signal propagation at ultra-high frequencies, while its woven glass reinforcement ensures durability during handling and assembly. Unlike some high-frequency materials, RO3203 is also lead-free process compatible, aligning with global environmental standards.

RO3203 Key Features

The material’s features are tailored to meet the strict demands of ultra-high-frequency applications, combining electrical excellence with mechanical resilience:

| Feature | Specification |

| Material Composition | Ceramic-filled PTFE composite (woven fiberglass-reinforced) |

| Dielectric Constant (Dk) | 3.02 ± 0.04 at 10GHz/23°C |

| Dissipation Factor (DF) | 0.0016 at 10GHz/23°C |

| Decomposition Temperature (Td) | >500°C |

| Thermal Conductivity | 0.87 W/mK |

| Coefficient of Thermal Expansion (CTE) | X-axis: 13 ppm/°C; Y-axis: 13 ppm/°C; Z-axis: 58 ppm/°C (-55 to 288°C) |

| Process Compatibility | Lead-free process compatible |

| Flammability Rating | UL 94 V-0 |

Benefits

RO3203’s properties translate to tangible advantages for the PCB, addressing key challenges in ultra-high-frequency design and volume manufacturing:

Ultra-High-Frequency Performance: Low DF (0.0016) and stable Dk (3.02 ± 0.04) enable reliable operation beyond 40 GHz.

Mechanical Stability: Woven glass reinforcement improves rigidity, making the PCB easier to handle during assembly and resistant to warpage.

Thermal Compatibility: Low in-plane CTE (13 ppm/°C for X/Y axes) matched to copper prevents solder joint failure during thermal cycling, supporting reliable surface-mounted assemblies.

Cost-Effectiveness: Economically priced for volume manufacturing, reducing total production costs without sacrificing high-frequency performance.

Surface Smoothness: Enables finer line etching tolerances for precise high-frequency circuit routing.

Safety & Compliance: UL 94 V-0 flammability rating and lead-free compatibility meet global safety and environmental standards.

Typical Applications

This PCB is designed for use in critical electronic systems, including:

-Automotive: Collision avoidance systems, GPS antennas

-Wireless Communications: Base station infrastructure, LMDS (Local -Multipoint Distribution Service), wireless broadband, microstrip patch antennas

-Satellite & Telecom: Direct broadcast satellites (DBS), wireless telecommunications systems, datalink on cable systems

-Industrial & Consumer: Remote meter readers, power backplanes

Availability: Worldwide

This PCB is globally accessible for production and delivery, addressing the logistical needs of multi-region high-frequency projects.

|