| Sign In | Join Free | My burrillandco.com |

|

| Sign In | Join Free | My burrillandco.com |

|

| Ask Lasest Price | |

| Brand Name : | Bicheng |

| Model Number : | BIC-332.V1.0 |

| Certification : | UL, ISO9001, IATF16949 |

| Price : | USD9.99-99.99 |

| Payment Terms : | T/T |

| Supply Ability : | 5000PCS per month |

| Delivery Time : | 8-9 working days |

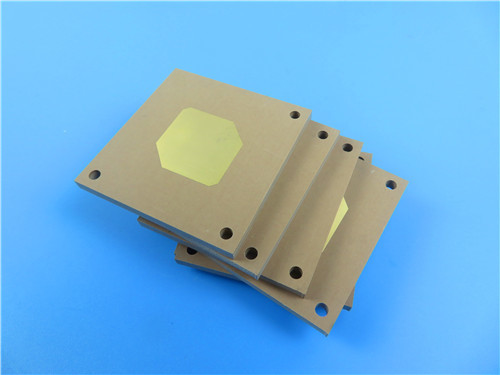

This high-performance 2-layer PCB is built with Rogers TMM4—a premium thermoset microwave material composed of ceramic, hydrocarbon, and thermoset polymer composite. Engineered for robust RF/microwave applications, it combines the mechanical resilience of ceramic with the process compatibility of traditional materials, eliminating the need for specialized fabrication techniques.

PCB Specification

| Parameter | Details |

| Base Material | Rogers TMM4 (ceramic-hydrocarbon thermoset polymer composite core) |

| Layer Count | 2-layer rigid PCB |

| Board Dimensions | 47mm x 118mm (1 piece)±0.15mm |

| Minimum Trace/Space | 5/7 mils |

| Minimum Hole Size | 0.35mm |

| Via Type | No blind vias (thru-hole vias only) |

| Finished Board Thickness | 1.6mm |

| Finished Copper Weight (Outer Layers) | 1oz (equivalent to 1.4 mils / 35 μm per layer) |

| Via Plating Thickness | 20 μm |

| Surface Finish | Silver and Gold Plating (Gold over Silver) – ensures corrosion resistance, reliable soldering, and long-term contact performance |

| Silkscreen | Top: White; Bottom: No |

| Solder Mask | Top: Green; Bottom: No |

| Quality Assurance | 100% Electrical test prior to shipment |

PCB Stack-up Details

| Layer Type | Material/Description | Thickness |

| Copper Layer 1 (Outer) | Conductive copper (finished) | 35 μm (1oz) |

| Dielectric Core | Rogers TMM4 | 1.524 mm (60 mils) |

| Copper Layer 2 (Outer) | Conductive copper (finished) | 35 μm (1oz) |

Material Overview: Rogers TMM4

Rogers TMM4 is a specialized thermoset microwave laminate designed to bridge the gap between ceramic and PTFE materials—offering strong mechanical/chemical properties without requiring specialized production techniques. Its ceramic-hydrocarbon-thermoset polymer composition delivers exceptional reliability for stripline and microstrip applications, including wire-bonding (no pad lifting or substrate deformation) and plated through-holes. Unlike traditional PTFE laminates, TMM4’s thermoset resin base ensures compatibility with all common printed wiring board (PWB) processes, simplifying fabrication while maintaining high performance for RF/microwave circuits.

Key Material Features

| Specification | Value |

| Material Type | Ceramic-hydrocarbon thermoset polymer composite |

| Dielectric Constant (Dk) | 4.50 ± 0.045 |

| Dissipation Factor (tanδ) @ 10 GHz | 0.0020 |

| Thermal Coefficient of Dk (TCDk) | 15 ppm/°K |

| Coefficient of Thermal Expansion (CTE) | X-axis: 16 ppm/°K; Y-axis: 16 ppm/°K; Z-axis: 21 ppm/°K |

| Decomposition Temperature (Td, TGA) | 425 °C |

| Thermal Conductivity | 0.7 W/mK |

| Moisture Absorption | 0.07% – 0.18% |

| Available Thickness Range | 0.0015 – 0.500 inches (±0.0015 inches) |

| CTE Compatibility | Matched to copper |

Core Benefits

Superior Mechanical Stability: Resists creep and cold flow, ensuring long-term dimensional integrity even under stress (e.g., vibration in satellite systems).

Chemical Resistance: Withstands process chemicals used in PCB fabrication, reducing damage and improving yield rates.

Reliable Wire-Bonding: Thermoset resin base eliminates pad lifting or substrate deformation—critical for high-precision RF/microwave components.

High Plated Through-Hole Reliability: Ideal for multi-layer scalability, with consistent performance across production runs.

Standard Process Compatibility: Works with all common PWB manufacturing techniques, no specialized equipment required (lowers production complexity and cost).

Copper-Matched CTE: X/Y-axis CTE (16 ppm/°K) matches copper, minimizing thermal stress on solder joints and extending component lifespan.

Typical Applications

This PCB is optimized for high-performance RF/microwave systems requiring reliability and process flexibility, including:

-RF and Microwave Circuitry

-Power Amplifiers and Combiners

-Filters and Couplers

-Satellite Communication Systems

-Global Positioning Systems (GPS) Antennas

-Patch Antennas

-Dielectric Polarizers and Lenses

-Chip Testers

|